Follow Us

Mail ID: info@bew.co.in

Find Us: Ramtekdi Industrial Area, Hadapsar, Pune, Maharashtra 411013

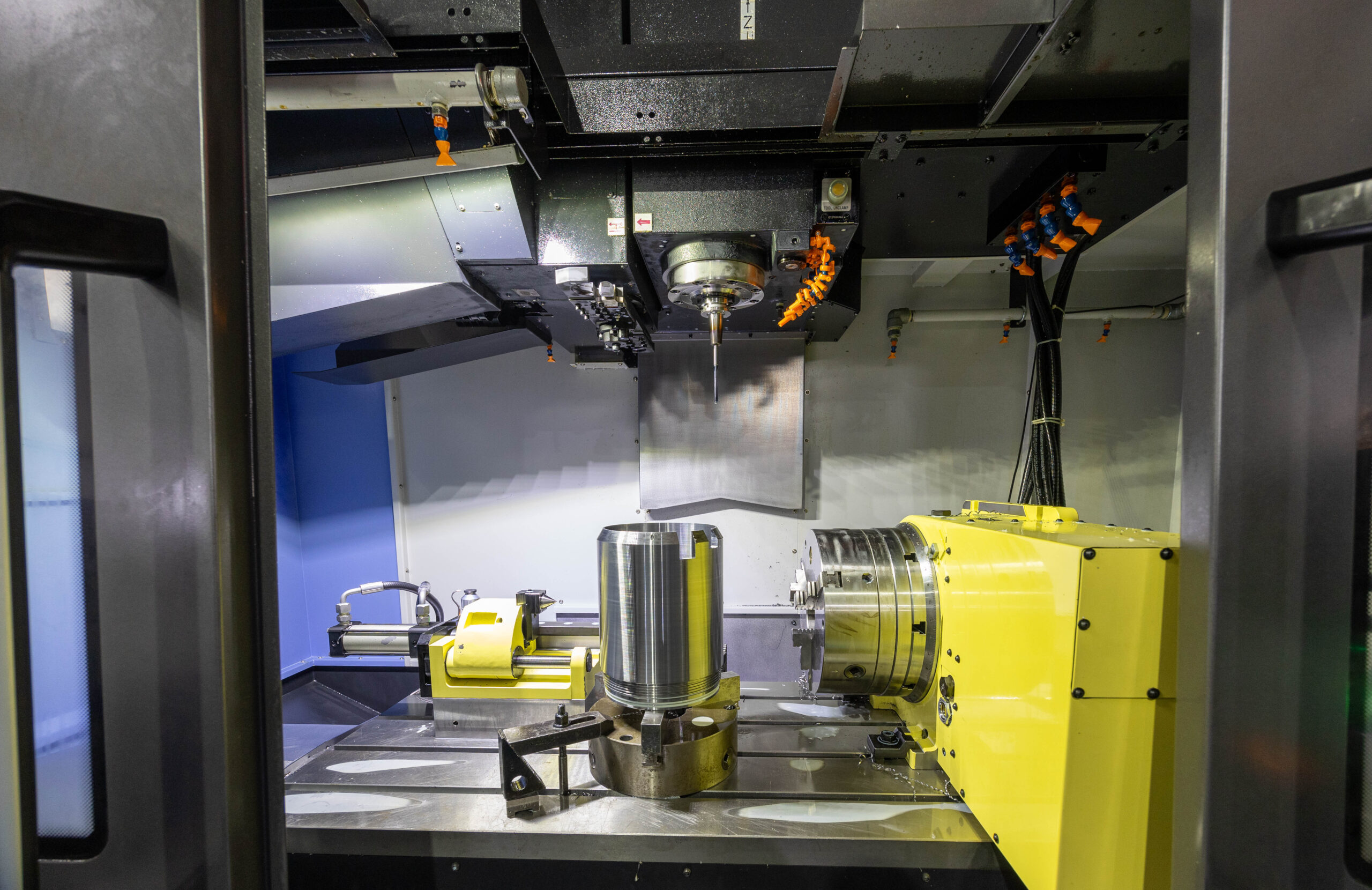

Every part we craft undergoes a meticulous process on advanced CNC and conventional machines, ensuring optimal performance and quality in every piece.

Our precision milling processes integrate advanced CNC capabilities with the expertise to handle complex and high-tolerance requirements, delivering consistent quality for demanding applications.

Precision Milling for Complex Parts

Leveraging CNC technology, we deliver high-quality components with tight tolerances, ensuring accuracy and repeatability essential for industries that require precision-engineered parts.

Flexible Material Compatibility

Our milling centers are equipped to work with a wide range of materials, allowing us to produce parts with intricate geometries and achieve high precision across different materials.

Advanced Multi-Axis Machining

Utilizing state-of-the-art 3-Axis, 4-Axis, 5-Axis, and even 7-Axis machines (such as the Mazak I-300), we can machine intricate 3D shapes with tight tolerances, ensuring detailed and complex part production.

Enhanced Accuracy with Renishaw Probing Systems

Equipped with Renishaw probing technology, including touch and tool-setting probes, we ensure enhanced accuracy and efficiency across machining processes, minimizing errors and maximizing quality.

Our Milling Expertise

We design and manufacture custom jigs and fixtures to optimize the efficiency of complex machining operations, ensuring repeatability and accuracy at every stage of production.

Our facilities are equipped with 3-Axis, 4-Axis, 5-Axis, and 7-Axis machines, allowing us to machine detailed parts with complex geometries and exact tolerances.

Each project adheres to ISO 9001-certified quality assurance protocols, with meticulous checks at each stage to deliver durable, high-quality components that meet precise client specifications.

Whether you need custom-engineered parts or consultation for your next project, BEW is here to help you!

We specialize in milling tappet valves, injectors, weight carriers, shafts, and other precision-engineered components tailored for demanding industries.

Yes, our team designs custom jigs and fixtures in-house to meet specific project requirements, ensuring seamless production.

Our ISO 9001-certified processes, combined with meticulous quality checks at each stage, ensure that every component meets exacting standards.

Bright provides milling solutions for automotive, aerospace, heavy machinery, oil and gas, and more.

Yes, with our mix of CNC and conventional machines, we are equipped to handle both small and large-scale production with consistent quality.